Michael Elson

President

Light Tool Supply

For

as long as I can remember, I have been surrounded by tools. As a young

boy I worked summers packing orders and unloading trucks at my father's

tool and supply company. After graduating from college, I immediately

went to work full-time for my father and have been in this industry ever

since. Over the years I have learned this business inside and out and

have spent many hours using that knowledge to improve the mail order

supply business. I have seen that business change drastically over the

years. The most dramatic change is from a business based on the paper

catalog to one based on products sold via the internet. Subsequently,

after many years of experience, I decided to create my own company to do

what I know best. Light Tool Supply is now quickly bringing tools to

loyal customers at the best prices possible. I encourage you to use our

vast experience as a resource for all your tooling needs. If you see

something on our website that you do not feel is the best price, please

feel free to email me directly at michael@lighttoolsupply.com. I also

would like you to email me or my staff with any manufacturer's Part#

from our long list of vendors at the bottom of this page for a low price

quote. Additionally, do not hesitate to contact Light Tool Supply with

any of our competitors' part numbers. It would be my pleasure to cross

reference those part numbers with ours and beat their prices! I realize

there are many companies to choose from; I hope you will choose Light

Tool Supply.

Thank you,

Michael Elson

President

Light Tool Supply

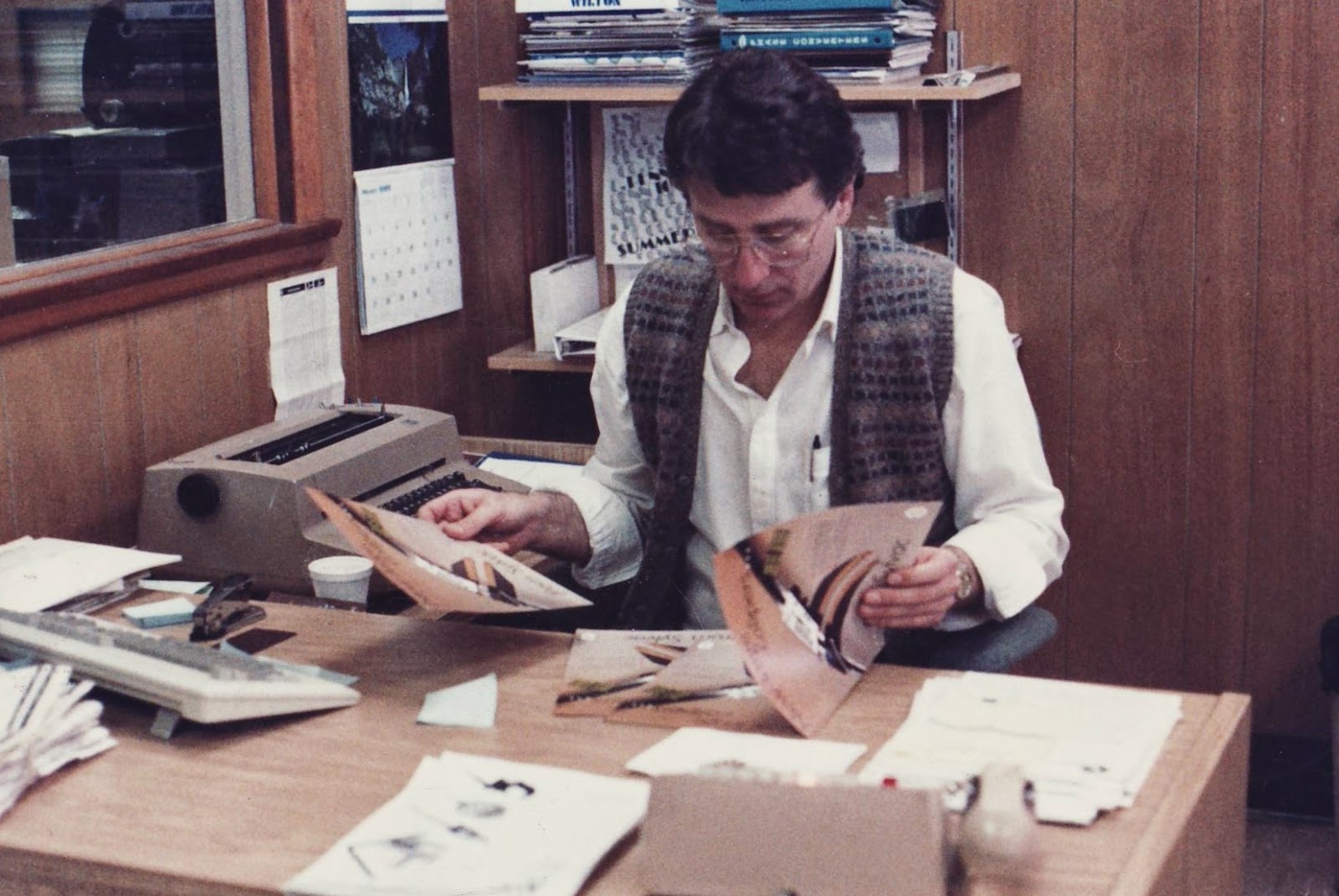

Picture-

Michael Elson, President of Light Tool Supply working in machine shop. (Picture taken Maplewood NJ 1994)

Picture-

Michael Elson, President of Light Tool Supply visits Mitutoyo Office in Germany (Picture taken in Germany 1994)

Picture-My Father, Gene Elson. Current President and Founder of

Penn Tool Co. Inc. (Picture taken Newark NJ 1967)

Picture-My Mother,

Phyllis Elson, working at an Industry Trade Show 1972

What is the warranty on your tools?

Most of the warranties are by the mfg and are for one year. Some are

more or less than one year depending on the mfg. Please inquire on

length of warranty before you purchase if concerned.

Do you Ship Outside the United States?

Yes. Light Tool Supply is happy to ship outside the U.S. You can contact

us prior to ordering or simply place the order online and we will get

back to you. We have found that small light packages(under 5 pounds) can

be shipped very economically through USPS or DHL. For questions contact

info@lighttoolsupply.com

Who pays for duties and taxes on International Orders?

The customer has to pay the duties and taxes to the delivery company

upon receiving the order. These fees are not included in the shipping

charge billed by Light Tool Co. These fees are individually determined

by your government. If you would like more information please email

info@lighttoolsupply.com

How do I calculate shipping?

Most shipping is calculated automatically before you finish paying for

your order. In the case of items that are over 150 lbs and must go by

truck, shipping is also calculated automatically. However we may need to

contact you about additional charges such as residential delivery and

Liftgate Truck Charge. We can also ship truck shipments to your local

Truck Terminal for you to pick up. For inquires email

info@lighttoolsupply.com

What do I do if I receive an order damaged?

Please take extra care to make sure the box or pallet (truck shipments)

is delivered in good condition before you sign for it. Light Tool Supply

can not accept responsibility for damaged items you sign for in good

condition.