Light Tool Supply Announces Its Third Anniversary

Light Tool Supply is located in Maplewood, New Jersey and supplies industrial tooling and metalworking supplies online to customers all over the world. The family-owned business focuses its efforts on providing a wide range of inventory from many manufacturers at the lowest price possible.

Maplewood, NJ (PRWEB) March 28, 2013

Light Tool Supply, a family-owned business and an online superstore of

industrial tooling and metalworking supplies announced that as of March

5, the company had officially completed its third year in business.

Started in 2010 by Michael Elson, Light Tool Supply has wrapped up three

successful years offering a wide array of industrial tooling supplies

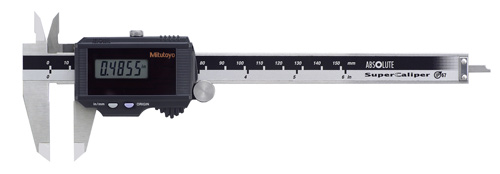

and metalworking tools online through its eCommerce website - LightToolSupply.com.Light Tool Supply President, Michael Elson, said being able to sell industrial tooling machinery and precise measuring instruments online has helped the company stay profitable and expand its customer base. “Three years is a hallmark for any business,” Elson said. “Focusing on metalworking supplies and measuring tools by the top manufactures in the industry, enables Light Tool Supply to supply thousands of different products quickly and at the lowest costs. It has been a real factor in our ongoing business success,” Elson said.

Michael Elson brings more than 40 years of experience in the industrial tooling and metalworking supplies industry to his operation of Light Tool Supply. In addition to managing the day to day duties of the business, Elson serves as Vice President of Penn Tool Co., which is based in Maplewood, New Jersey. He fondly recalls growing up helping his father around the family’s tool shop.

“I started working in the metalworking supply business when I was pretty young,” he said. “For as long as I can remember, I have been surrounded by tools, whether it was packing orders and unloading trucks during the summer at my father’s tool supply company or working full time for him after graduating from college. This business is in my blood and I have a natural affinity for it.”

Elson keeps the focus of Light Tool Supply on streamlining ordering tooling and supplies so that the process is easy for customers and on offering an enormous amount of product at some of the lowest prices on the internet. His strategy allows Light Tool Supply to offer metalworking machinery by firms like Baileigh Industrial and precise measuring instruments by respected manufacturers like Mitutoyo. Elson stocks Light Tool Supply with inventory from hundreds of manufacturers and prides himself on being able to get any part for any customer at the lowest price possible. “If a customer sees something on our website that he does not feel is the best price, he should email me directly so that we can do our best to match the price.”

Elson invites customers to email his staff with a request for any part number from Light Tool Supply’s long list of vendors.